Regular EPP

Rigidity EPP

FR EPP

Hollow EPP

Conductive EPP

EPE

Bio-based EPP

E-PLA

E-TPU

Expanded Polypropylene (EPP) is a highly versatile closed-cell bead foam that provides a unique range of properties.

EPP can be made in a wide range of densities, from 15 to 200 grams per litre, which are transformed by moulding into densities ranging from 18 to 260 grams per litre. Individual beads are fused into final product form by the steamchest moulding process resulting in a strong and lightweight shape.

100% Recyclable Thermal Insulation Strength Lightweight Impact Absorption

Sound Deadening

| Physical properties | TEST STANDARD | UNIT | 20kg/m³±10% | 30kg/m³±10% | 40kg/m³±10% | 50kg/m³±10% | |||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| Standards | Result | Standards | Result | Standards | Result | Standards | Result | ||||

| Density | ISO 845 | kg/m³ | 18-22 | 22 | 27-33 | 32.5 | 36-44 | 38 | 45-55 | 46.2 | |

| Tensile Strength | ISO 1926 | kPa | >180 | 296 | >240 | 451 | >300 | 675 | >400 | 571 | |

| Tensile Elongation | % | >12% | 16 | >12% | 22 | >10% | 14 | >10% | 18 | ||

| Compression Stress | 25% | ISO 844 | kPa | ≥14 | 82 | ≥66 | 185 | ≥142 | 301 | ≥215 | 343 |

| 50% | >80 | 157 | >120 | 232 | >180 | 376 | >300 | 399 | |||

| Compression Set | ISO 1856-C | % | <35% | 26.23 | <45% | 36.92 | <45% | 37.25 | <45% | 37.51 | |

| Flammability | GB 8410 | mm/min | ≤80 | 78.96 | ≤80 | 62.72 | ≤80 | 51.14 | ≤80 | 43.79 | |

| Physical properties | TEST STANDARD | UNIT | 60kg/m³±10% | 70kg/m³±10% | 80kg/m³±10% | 90kg/m³±10% | |||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| Standards | Result | Standards | Result | Standards | Result | Standards | Result | ||||

| Density | ISO 845 | kg/m³ | 54-66 | 60.6 | 63-77 | 65.7 | 72-88 | 79.5 | 81-99 | 85.6 | |

| Tensile Strength | ISO 1926 | kPa | >450 | 856 | >500 | 961 | >600 | 1124 | >700 | 1210 | |

| Tensile Elongation | % | >10% | 25 | >10% | 24 | >10% | 24 | >10% | 24 | ||

| Compression Stress | 25% | ISO 844 | kPa | ≥295 | 450 | ≥381 | 488 | ≥473 | 591 | ≥572 | 636 |

| 50% | >380 | 523 | >450 | 567 | >550 | 986 | >650 | 1051 | |||

| Compression Set | ISO 1856-C | % | <45% | 37.76 | <45% | 37.98 | <45% | 38.22 | <45% | 38.41 | |

| Flammability | GB 8410 | mm/min | ≤80 | 40.32 | ≤80 | 39.28 | ≤80 | 37.54 | ≤80 | 36.2 | |

| Physical properties | TEST STANDARD | UNIT | 120kg/m³±10% | 150kg/m³±10% | 180kg/m³±10% | 200kg/m³±10% | |||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| Standards | Result | Standards | Result | Standards | Result | Standards | Result | ||||

| Density | ISO 845 | kg/m³ | 108-132 | 112.8 | 135-165 | 142.37 | 162-198 | 165.28 | 180-220 | 183.54 | |

| Tensile Strength | ISO 1926 | kPa | >900 | 1328 | >950 | 1691 | >1000 | 2064 | >1100 | 2282 | |

| Tensile Elongation | % | >8% | 28 | >8% | 19 | >5% | 20 | >5% | 21 | ||

| Compression Stress | 25% | ISO 844 | kPa | / | 838 | / | 1158 | / | 1344 | / | 1492 |

| 50% | >1000 | 1221 | >1500 | 1808 | >2100 | 2355 | >2500 | 2773 | |||

| Compression Set | ISO 1856-C | % | <45% | 38.87 | <45% | 39.01 | <45% | 39.23 | <45% | 39.56 | |

| Flammability | GB 8410 | mm/min | ≤80 | 34.09 | ≤80 | 30.66 | ≤80 | 29.48 | ≤80 | 27.26 | |

High Rigidity EPP

Under the same density, high-rigidity EPP is harder than regular one , and the comprehensive mechanical properties are better. It is more suitable for package solutions .

Light weight

High rigidity

Impact absorption

Energy absorption

| Physical properties | Test method | QB15P | B15P | QB30P | B30P | |

|---|---|---|---|---|---|---|

| Density/(g/L) | / | 49 | 49 | 25 | 26 | |

| Tensile Strength/kpa | GB/T 6344 | 1273 | 1030 | 740 | 570 | |

| Tensile Elongation/% | 38 | 48 | 36 | 49 | ||

| Compression Stress/kpa | 10% strain | GB/T 8813 | 375 | 273 | 120 | 74 |

| 25% strain | 434 | 322 | 154 | 114 | ||

| 50% strain | 533 | 409 | 225 | 189 | ||

| 75% strain | 887 | 729 | 444 | 449 | ||

| Shrinkage/% | / | 2.2-2.4 | 2.2-2.4 | 2.2-2.4 | 2.2-2.4 | |

| Molding pressure/bar | / | 2.6-3.0 | 2.4-2.6 | 2.6-3.0 | 2.4-2.6 | |

Note:The above is the typical value from laboratory.

High Flame Retardant EPP

High flame-retardant EPP has excellent flame-retardant properties and can achieve the function of self-extinguishing from the fire.

Excellent flame retardant performance: The oxygen index test result can reach more than 30%, and the flame retardant grade can reach more than HF-1 (UL94-2015)

There is little burning smoke and no dripping, which can achieve the effect of self-extinguishing away from the fire, which is safe and environmentally friendly

Excellent thermal insulation performance: thermal conductivity ≤0.033W/(m.k)

| Physical properties | Test method | Products | |||

|---|---|---|---|---|---|

| C82 | C83 | C84 | |||

| Density/(g/L) | / | 42-46(18P) | 42-46(18P) | 42-46(18P) | |

| Tensile Strength/kpa | GB/T 6344 | 560 | 554 | 544 | |

| Tensile Elongation/% | 27 | 26 | 24 | ||

| Compression Stress/kpa | 10% strain | GB/T 8813 | 175 | 191 | 167 |

| 25% strain | 225 | 213 | 209 | ||

| 50% strain | 303 | 308 | 287 | ||

| 75% strain | 556 | 613 | 513 | ||

| Oxygen Index/% | GB/T 2406.1 | 24↑ | 28↑ | 30↑ | |

| Flammability rate | UL94 | HF-1 | |||

| Thermal Conductivity/W/(m.k) | GB/T 10294 | 0.04 | 0.04 | 0.033 | |

| Shrinkage/% | / | 1.8-2.2 | 1.8-2.2 | 1.8-2.2 | |

| Molding pressure/bar | / | 2.8↑ | 2.8↑ | 2.8↑ | |

Note:The above is the typical value from laboratory.

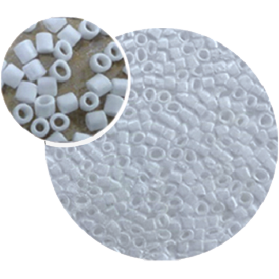

Hollow EPP

Hollow EPP has unique hollow cylindrical structure,and it allows many irregular holes inside the molded part.

While being lighter than regular EPP , it also has excellent air permeability and sound absorption performance.

Air permeability Sound absorption Lighter: 15%~25% than regular one

High production efficiency: NO pre-pressing, lower moulding pressure

| Physical properties | Test method | Hollow EPP | Flame Retardant EPP | Regular EPP | |

|---|---|---|---|---|---|

| Density/(g/L) | / | 26 | 26 | 26 | |

| Tensile Strength/kpa | GB/T 6344 | 387 | 485 | 420 | |

| Tensile Elongation/% | 31 | 36 | 43 | ||

| Compression Stress/kpa | 10% strain | GB/T 8813 | 117 | 99 | 91 |

| 25% strain | 156 | 149 | 120 | ||

| 50% strain | 257 | 217 | 206 | ||

| 75% strain | 491 | 481 | 419 | ||

| Flammability/(mm/min) | GB/T 8410 | Self-extinguishing in 15s | 75-80 | 85-90 | |

| 1.0L sample/g | / | 27 | 33 | 32 | |

| 60mm sample block sound absorption | GB/T 18696.2 | 0.7 | 0.1 | 0.1 | |

| Molding pressure/bar | / | 1.8-2.2 | 2.8-3.2 | 2.2-2.6 | |

Note:The above is the typical value from laboratory.

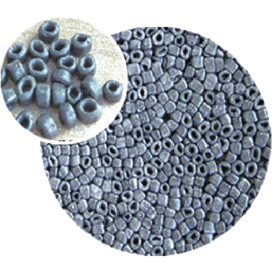

Conductive EPP

With conductive properties: semi-conductive /highly conductive / highly conductive and flame retardant.

Unique closed cell structure makes its electrical conductivity stable.

Good water resistance, prolongs the service life of conductive materials.

Excellent wear resistance, toughness, impact resistance and temperature resistance.

Self-extinguishing away from the fire.

| Physical properties | Test method | GDH(6) | GDH(3) | GZDH | ||

|---|---|---|---|---|---|---|

| 15P | 30P | 15P | 15P | |||

| Density/(g/L) | / | 48-53 | 24-27 | 50-55 | 46-50 | |

| Tensile Strength/kpa | GB/T 6344 | 600 | 390 | 400 | 271 | |

| Tensile Elongation/% | 29 | 29 | 23 | 17 | ||

| Compression Stress/kpa | 10% strain | GB/T 8813 | 207 | 101 | 126 | 103 |

| 25% strain | 265 | 138 | 161 | 137 | ||

| 50% strain | 368 | 207 | 221 | 288 | ||

| 75% strain | 687 | 408 | 440 | 323 | ||

| Shrinkage/% | / | 2.0-2.4 | 2.4-2.8 | 2.4-3.0 | 3.1-3.4 | |

| Molding pressure/bar | Moulding test | 2.4↑ | 2.4↑ | 3.0↑ | 3.0↑ | |

| Resistance value/Ω | GB/T 6344 | 106-9 | 106-9 | 103-5 | 103-5 | |

| Friction voltage/V | SJ/T 10694 | ≤100 | ≤50 | |||

| Decay time/S | ≤1 | ≤0.5 | ||||

| Oxygen Index/% | GB/T 2406.2 | 20 | 24-26 | |||

Note:The above is the typical value from laboratory.

epe

EPE (Expandable Polyethylene) ,We have developed high-rate EPE products to further broaden the application areas of EPE.

The cell size is uniform and the closed cell rate is high, with extremely excellent resilience.

The colour of the molded part is well-proportioned, and the hand feel is better than EPP.

Environmentally friendly.

| Physical properties | Test method | Products | |||

|---|---|---|---|---|---|

| Density/(g/L) | GB/T 6343-2009 | 37-41(18P) | 31-35(25P) | 22-25(35P) | |

| Tensile Strength/kpa | GB/T 13022-1991 | 320.29 | 299.54 | 288.20 | |

| Tensile Elongation/% | 55.20 | 68.53 | 79.68 | ||

| Compression Stress | 10% strain/kpa | GB/T 8813-2008 | 42.89 | 40.76 | 38.62 |

| 25% strain/kpa | 85.75 | 73.39 | 67.25 | ||

| 50% strain/kpa | 158.47 | 139.79 | 134.21 | ||

| 75% strain/kpa | 377.91 | 358.53 | 348.46 | ||

| Shrinkage/% | / | 2.6-3.2 | 2.8-3.4 | 2.8-3.4 | |

| Molding pressure/bar | Moulding test | 0.7-0.9 | 0.7-0.9 | 0.7-0.9 | |

Note:The above data is tested by 40cm*36cm*6cm cube.

Bio-based EPP

Bio-based EPP mainly refers to environmentally friendly polypropylene composite foam material based on straw, sugarcane and other lignocellulosic agricultural and forestry wastes other than grain. The application fields involve Industrial turnover, cold chain logistics, electronic and electrical product packaging, civilian leisure and other fields.

Widely used in the field of disposable packaging that is not conducive to the establishment of a recycling system.

Replace existing foam materials such as EPP and EPS to reduce the consumption of petrochemical resources and reduce environmental pollution.

It has been officially certified by the American BETA laboratory for bio-based materials, with a biological C14 content of 28%.

Can apply for the European green label for Bio-based bio-based materials.

| Physical properties | TEST STANDARD | Biobasd EPP | Regular EPP | |

|---|---|---|---|---|

| Color | / | White | White | |

| Bio-based component content/% | / | ≥20 | 0 | |

| Volatile content/% | / | 0 | 0 | |

| Density/(g/L) | ISO 845 | ~50 | ~50 | |

| Tensile Strength/kpa | GB/T 6344-2008 | 1131 | 1202 | |

| Tensile Elongation/% | GB/T 6344-2008 | 52.4 | 40.0 | |

| Compression Stress/kpa | 10% | GB/T 8813 | 198.0 | 221.7 |

| 25% | 271.5 | 300.6 | ||

| 50% | 365.2 | 415.6 | ||

| 75% | 791.8 | 830.3 | ||

| Shrinkage/% | / | 1.8-2.2 | 1.8-2.2 | |

| Molding pressure/bar | / | 2.0-2.4 | 2.0-2.6 | |

Note:The above is the typical value from laboratory.

PLA

Polylactide (PLA), is a polyester polymer obtained by polymerization of lactic acid as the main raw material. It is a new type of biodegradable material. Using supercritical CO2 autoclave foaming process to physically foam the modified PLA particles, a degradable E-PLA lightweight material can be obtained.

Widely used in the field of disposable packaging that is not conducive to the establishment of a recycling system.

Replace EPS foam, reduces the pollution of EPS foam to the environment, and has excellent cushioning and protection performance.

Can apply for full biodegradable certification mark.

| Physical properties | TEST STANDARD | E-PLA | Regular EPP | |

|---|---|---|---|---|

| Color | / | White | White | |

| Volatile content/% | / | 0 | 0 | |

| Density/(g/L) | ISO 845 | 50 | 50 | |

| Compression Stress/kpa | 10% | GB/T 8813 | 275 | 191 |

| 25% | 336 | 243 | ||

| 50% | 449 | 343 | ||

| 75% | 825 | 704 | ||

| Shrinkage/% | / | 1.0-1.2 | 1.8-2.0 | |

| Water absorption rate/% | / | ≤2 | ≤2 | |

| Molding pressure/bar | 0.8-1.2 | 0.8-1.2 | 2.0-2.6 | |

Note:The above is the typical value from laboratory.

E-TPU

Foamed thermoplastic polyurethane elastomer (E-TPU) is a new type of foam material with excellent performance. E-TPU products are soft, light and breathable, and are currently a new type of material in the field of high-end shoe materials. In addition, it also has very broad application prospects in the fields of shock absorption, packaging, car interiors, sporting goods, children's toys, and thermal insulation. E-TPU is environmentally friendly, fully recycled, which is an extremely excellent Green material.

High yellowing resistance level.

High resilience.

low molding pressure, low energy consumption.

| Physical properties | Test method | Result |

|---|---|---|

| Hardness | GB/T 3903.4 邵氏C | 30-47 |

| Wearable | GB/T 9867 | ≤250mm³ |

| Density | GB/T 533 | 0.18-0.27g/cm³ |

| Compression | HG/T 2876 | ≤30% |

| Rebound | GB/T 1681 | ≥60% |

| Foldable | GB/T 3903.1 | Passed |

| Yellowing resistance grade | HG/T 3689-2014 | A 24H ≥4level |

| B 3H ≥4level | ||

| Tear strength | GB/T 1080 | ≥4N/mm |

| Tensile Strength | GB/T 6344 | ≥1.5MPa |

| Elongation | GB/T 6344 | GB/T 6344 |